Nanoengineering Opens the Door For Better Bone Transplants

NewsThe Context: Human bone requires a certain environment within the body to grow, and recreating this environment outside of the body has enormous potential for understanding disease and creating healthy bone grafts from stem cells for transplantation.

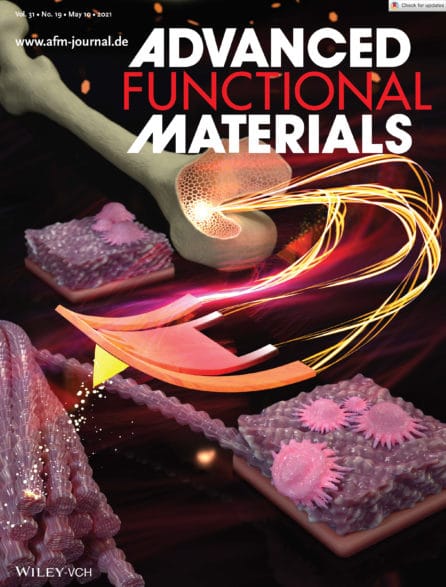

The Study: New precise, inexpensive, and reusable bone-mimetic replicas were developed by NYSCF – Ralph Lauren Senior Research Investigator Giuseppe Maria de Peppo, PhD, and New York University Professor of Chemical and Biomolecular Engineering Elisa Riedo, PhD, by leveraging nanotechnology, to let scientists engineer surfaces where stem cells – including bone-forming stem cells – can mature as they would in the human body. The study appears in Advanced Functional Materials.

The Importance: This method can create surfaces with detailed features smaller than a billionth of a meter that foster the growth of any cell type, opening the door for more accurate study of disease and regenerative medicine.

Bone stem cells are supported by an extracellular matrix (ECM) – a mix of molecules that keep cells healthy and active which is difficult to assemble artificially. Many labs have worked on recreating the complex structure of bone, but traditional methods lack the precision and fine resolution to fully recreate the bone environment where these cells reside. Our cells rely on physical cues from their environments to function properly, and capturing these physical structures is especially important for creating better bone grafts and implants.

In their study, the researchers developed an affordable method for generating reusable surfaces that could mimic the ECM and other characteristics of the biological environment, giving bone stem cells a home to mature in that closely resembles that of the human body.

How Does it Work?

The method uses a ‘hot nano-chisel’ to sculpt out a surface the exact architecture of a biological tissue (like the ECM) with features smaller than the size of a single protein, a billion times smaller than a meter.

The team used their tool to recreate the complexity of the bone ECM and demonstrated that this artificial bone replica supported the growth of bone-forming stem cells.

Importantly, the method is time- and cost-effective, and can be used to create reusable surfaces that support the growth of any cell type.

“This nanofabrication method, called tSPL, was pioneered in my lab and at IBM a few years ago,” remarked Dr. Riedo in a press release. “However, limitations in terms of throughput and biocompatibility of the materials have prevented until now its use in biological research. Here, we are very excited to have broken these barriers and to have led tSPL into the realm of biomedical applications.”

Why Does it Matter?

These replicas could help researchers better understand diseases by examining how diseased cells mature and interact with their surroundings, and bone grown from stem cells using these replicas could be used to test drugs or treat bone defects.

“This new method will help researchers study diseases in a way that more faithfully reflects the environment of the human body, opening the door for better understanding of a disease’s underlying biology and enabling advanced drug screening,” said Dr. de Peppo. “As a tissue engineer, it is especially exciting that this new platform could also help us create more effective orthopedic implants to treat skeletal and maxillofacial defects resulting from injury or disease.”

Journal article:

Cost and Time Effective Lithography of Reusable Millimeter Size Bone Tissue Replicas With Sub‐15 nm Feature Size on A Biocompatible Polymer

Xiangyu Liu, Alessandra Zanut, Martina Sladkova‐Faure, Liyuan Xie, Marcus Weck, Xiaorui Zheng, Elisa Riedo, Giuseppe Maria de Peppo. Advanced Functional Materials (February, 2021). DOI: https://doi.org/10.1002/adfm.202008662